| Carbon Black Content | 30% - 50% | Customizable based on demand |

| Carrier Resin | PE / PP / PS / ABS | Compatible with universal polymers |

| Melt Index | 5 - 25 | g/10min (Tested as per ASTM D1238) |

| Density | 1.2 - 1.4 | g/cm³ |

| Dispersion Level | Excellent | Meets ISO standards for uniformity |

| Heat Resistance | ≥300 | ℃, No decomposition during high-temperature processing |

| Light Fastness | ≥7 | Blue Wool Scale (1-8 levels) |

| UV Resistance | High | Suitable for prolonged outdoor use |

| Dosage | 1% - 5% | Adjust based on color depth and application |

| Moisture Content | ≤0.1 | %, Ensures dry state |

| Particle Size | 2 - 3 | mm, Uniform granules for easy processing |

Common Universal Grade Granules Black Masterbatch Black Plastic Granules

Common Universal Grade Granules Black Masterbatch Black Plastic Granules are a widely used colorant, mainly used to provide stable and consistent black effects for various plastic products. This black masterbatch has the characteristics of strong versatility and wide applicability, and can be mixed with a variety of plastic raw materials to meet the coloring needs of different fields. Ordinary general-purpose black masterbatch black plastic particles are used in packaging, home appliances, automobiles, building materials and other industries. It can be used to make various black plastic products, such as packaging bags, containers, shells, parts, etc.

Description

This product uses LLDPE as the carrier and is processed with the pigment carbon black, which has dispersion, high black, and high brightness. Can be used in LDPE, LLDPE, PP, PA, ABS, ABS/PC alloy, and other recycled materials, with high-cost performance.

25 kg/ bag composite packaging bag. Store in a dry place.

Recommended storage period: If stored as instructed, up to one year, more than one year later, it is recommended to re-test the moisture content before use.

Common Universal Grade Granules Black Masterbatch, universal grade black masterbatch, is a plastic granular material made from polymer by adding carbon black, dispersant and other additives. This black masterbatch is mainly used as a colorant and functional additive in the production of plastic products to improve the appearance quality and certain properties of plastic products.

Features:

Excellent coloring properties: Provides a deep, uniform black effect with high hiding power and good lightfastness.

Strong versatility: Suitable for a variety of polymer substrates, including PE (polyethylene), PP (polypropylene), PS (polystyrene), ABS, etc.

Excellent processing performance: the particles are uniform, easy to disperse, and do not affect the mechanical properties of the plastic substrate.

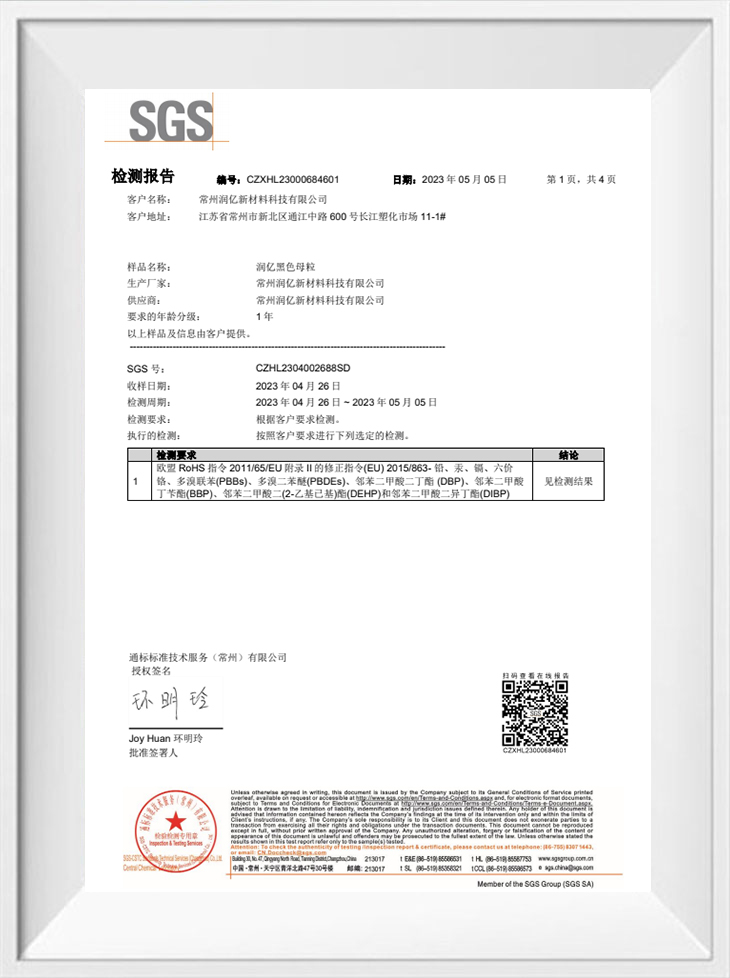

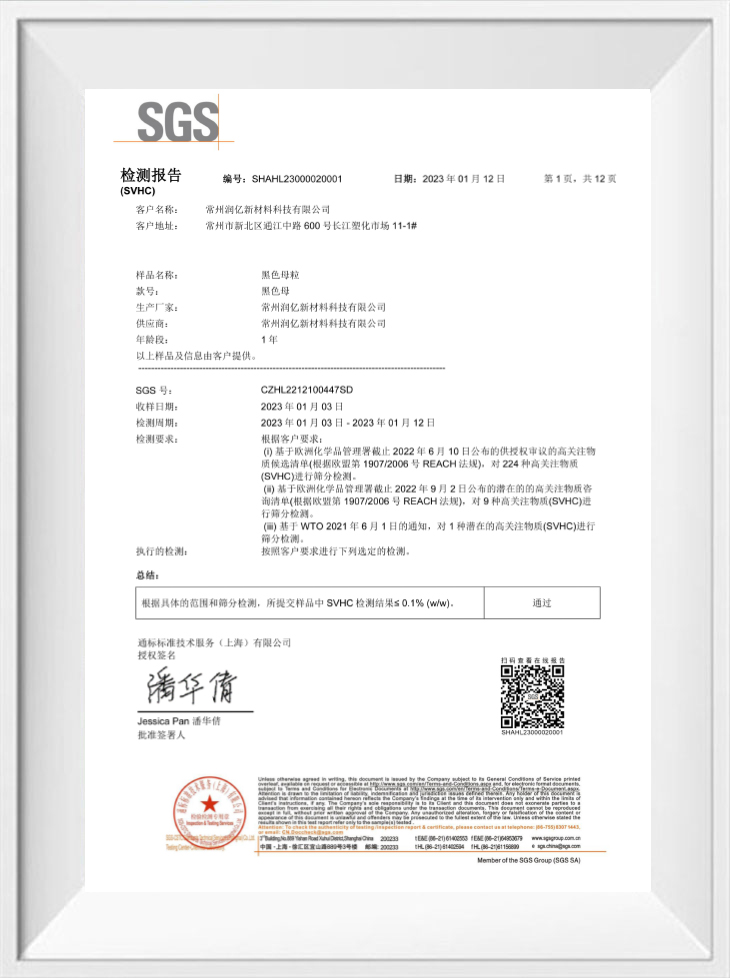

Environmentally friendly formula: non-toxic and harmless, in compliance with relevant environmental protection and food contact safety standards (if certified, please indicate).

High cost performance: low dosage, significant coloring effect, and reduced waste of raw materials.

Application scope and scenarios:

Plastic packaging industry:

Used to produce black plastic bags, garbage bags and packaging films.

Applicable to food grade packaging materials (must comply with relevant safety standards).

Household appliances and electronic product casings:

Used in the manufacture of household appliances (such as televisions, refrigerators, washing machines, etc.) and electronic equipment casings to provide high gloss or matte effects and improve appearance quality.

auto industry:

Used as a colorant in automotive interior parts, dashboards, bumpers and other parts to provide UV resistance, heat resistance and weather resistance.

Building materials and agricultural applications:

It is suitable for the production of plastic pipes, cable sheaths, geomembranes, greenhouse films and other products, with good durability and anti-aging properties.

Daily consumer goods:

Used to make daily necessities such as plastic buckets, basins, cups, stationery, etc. to enhance the visual appeal of the products.

Industrial containers:

When used in chemical storage tanks, plastic pallets and other products, it can provide anti-static and anti-corrosion functions (corresponding additives need to be added).

Get in Touch With Us

Who Are We?

Changzhou Runyi New Material Technology Co., Ltd.

We are

Wholesale Common Universal Grade Granules Black Masterbatch Black Plastic Granules Suppliers and

Wholesale OEM/ODM Common Universal Grade Granules Black Masterbatch Black Plastic Granules Factory.

Changzhou Runyi New Material Technology Co., Ltd. relying on the unique market and geographical advantages of the Yangtze River Delta, and through long-term unremitting efforts, has developed into a well-known color masterbatch production and sales enterprise that integrates research and development, production, sales, and export. Over the years, the company has cultivated a group of professional talents and has become the main force of the company, while accumulating rich production experience.

News

-

The Science of Black: Optimizing Polymer Performa...

The Engineering Role of Carbon Black Masterbatch In the polymer industry, the carbon black masterbatch is far more ...

READ MORE -

Material Science of Pigmentation: Achieving Carri...

The selection of a Carbon Black Masterbatch is a technical exercise that extends far beyond color matching. For B2B...

READ MORE -

Engineered Longevity: Carbon Black Masterbatch UV...

In applications demanding extended outdoor performance—such as pipes, geosynthetics, and agricultural films—the sta...

READ MORE -

Precision Pigmentation: Mastering the FPV and Dis...

For processors involved in manufacturing thin-gauge films, fine fibers, or sophisticated injection molded component...

READ MORE -

MFR Matching Principle: Optimizing White Masterba...

In the realm of polymer processing, achieving consistent color dispersion and flawless product quality is a fundame...

READ MORE

Common Universal Grade Granules Black Masterbatch Black Plastic Granules Industry knowledge

Universal Black Masterbatch: How Do Additives and Carrier Resins Enhance Plastic Products?

Universal black masterbatch serves as a crucial component in the plastics industry, enabling the efficient and effective coloring of plastic products. Central to its functionality are the additives and carrier resins it contains.

Additives in Universal Black Masterbatch

Additives play a pivotal role in universal black masterbatch formulations, offering various enhancements to the final plastic product. These additives are carefully selected based on the specific requirements of the application and the desired properties of the end product. Some common additives found in universal black masterbatch include:

UV Stabilizers: UV stabilizers protect plastic products from degradation caused by exposure to ultraviolet (UV) radiation, thereby extending their service life and maintaining their aesthetic appeal.

Antioxidants: Antioxidants inhibit the oxidation of plastic materials, which can lead to discoloration, brittleness, and degradation over time. By incorporating antioxidants, masterbatch manufacturers enhance the durability and longevity of plastic products.

Antistatic Agents: Antistatic agents reduce the buildup of static electricity on the surface of plastic products, preventing dust accumulation and improving their overall cleanliness and appearance.

Slip Agents: Slip agents reduce the coefficient of friction between plastic surfaces, facilitating easier handling, processing, and packaging of plastic products.

Flame Retardants: Flame retardants impart fire resistance to plastic products, reducing the risk of ignition and inhibiting the spread of flames in the event of a fire.

Processing Aids: Processing aids improve the flow properties of plastic resins during manufacturing processes such as extrusion, injection molding, and blow molding, resulting in smoother processing and enhanced product quality.

Carrier Resins in Universal Black Masterbatch

Carrier resins serve as the matrix in which additives and colorants are dispersed uniformly to form the masterbatch. The selection of carrier resins depends on factors such as compatibility with the base polymer, processing conditions, and desired properties of the final plastic product. Common types of carrier resins used in universal black masterbatch include:

Polyethylene (PE): PE-based carrier resins are widely used in universal black masterbatch formulations due to their excellent compatibility with a variety of base polymers, including polyethylene, polypropylene, and ethylene-vinyl acetate copolymers.

Polypropylene (PP): PP-based carrier resins offer good thermal stability, mechanical strength, and chemical resistance, making them suitable for applications requiring higher temperature processing and performance.

Polystyrene (PS): PS-based carrier resins are commonly used in applications where clarity, stiffness, and dimensional stability are paramount, such as food packaging and consumer goods.

Polyvinyl Chloride (PVC): PVC-based carrier resins are preferred for applications requiring excellent weatherability, chemical resistance, and electrical insulation properties, such as building materials, automotive components, and electrical cables.

Ethylene-vinyl Acetate (EVA): EVA-based carrier resins offer flexibility, low-temperature toughness, and good adhesion to various substrates, making them suitable for applications requiring softness, elasticity, and adhesion, such as flexible packaging and footwear.

Production Process and Quality Control

The production of universal black masterbatch involves meticulous control of the formulation, mixing, compounding, and pelletizing processes to ensure the uniform dispersion of additives and colorants within the carrier resin matrix. Quality control measures are implemented at every stage of production to monitor key parameters such as pigment concentration, dispersion quality, pellet size, and moisture content.

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى