Electret For Mask Masterbatch For PP Melt-Blowing Fabrics Master Batch

Mask electret masterbatch is a special material specially used for mask production. It is mainly used to solve the needs of polypropylene non-woven fabrics to absorb static electricity. The addition of electret masterbatch makes the mask more effective in capturing and filtering tiny particles in the air. PP melt blown cloth masterbatch is an important raw material in the production of melt blown cloth. Meltblown cloth is the key filter layer in the mask, and its performance directly determines the filtering effect of the mask. The use of PP melt-blown cloth masterbatch makes the melt-blown cloth have better uniformity and stability, thereby improving the filtration efficiency and production efficiency of the mask.

Description

With polypropylene as the base material, special additives are used to make the additives evenly dispersed in the master batch.

In the spinning process of melt-blown non-woven fabric, adding 2% to 5% can effectively increase the density and depth of charge trapping energy trap in melt-blown non-woven fabric, so as to improve the comprehensive filter effect and thermal attenuation resistance of melt-blown non-woven fabric. In the case of the same fiber fineness and gram weight, reduce the resistance of non-woven products, while improving the filter effect of non-woven products.

| High Electret Performance | Incorporates special electret agents to provide melt-blown fabrics with a lasting electrostatic charge, significantly improving filtration efficiency. |

| High Filtration Efficiency | Excellent interception capability for fine particles such as PM2.5, bacteria, and viruses. |

| Low Breathing Resistance | Ensures high filtration efficiency while maintaining low breathing resistance for enhanced comfort. |

| Excellent Processability | Compatible with PP resin, offers good fluidity, and is suitable for melt-blown processes, ensuring high production efficiency. |

| Long-lasting Stability | Electret effect remains stable even under high temperature and humidity conditions. |

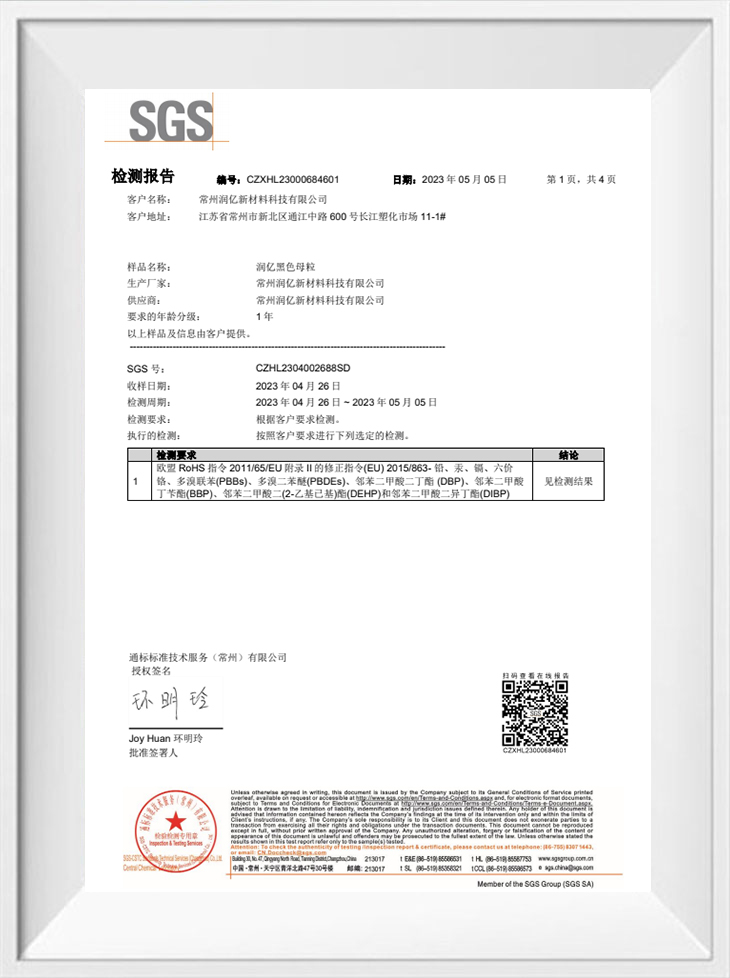

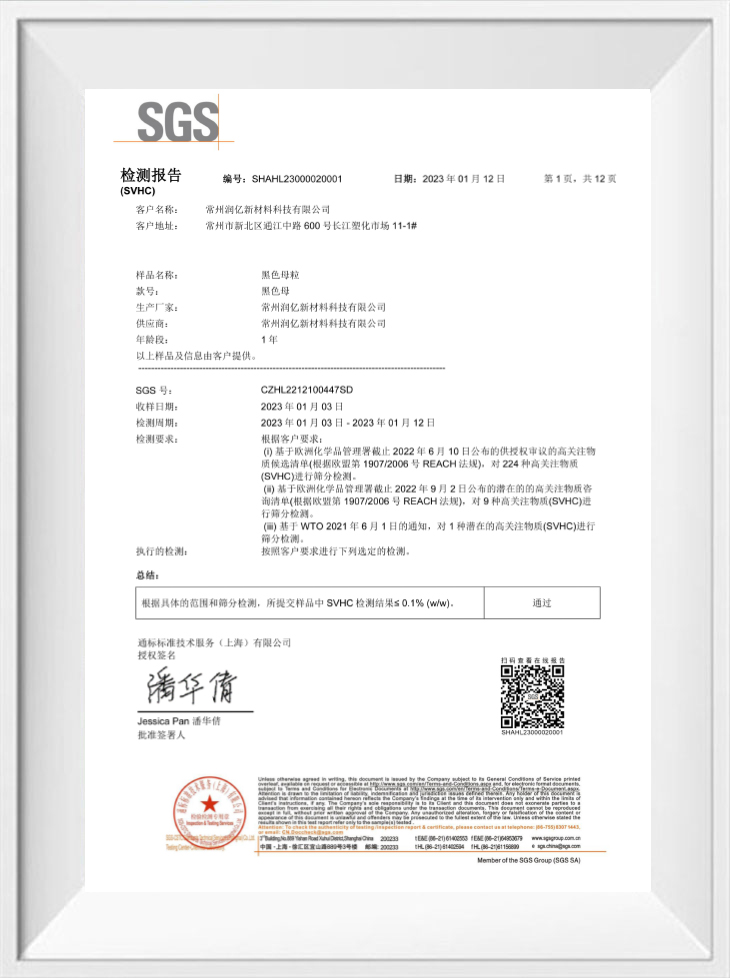

| Eco-friendly and Safe | Complies with RoHS, REACH, and other environmental standards, making it non-toxic and safe for medical and hygiene applications. |

Product Features

Uniform pigment dispersion: This product uses a special production process to evenly disperse carbon black pigment in the polyester matrix, avoiding pigment aggregation, thereby ensuring the consistency and stability of the fiber color.

Good coloring ability: It can provide polyester fibers with uniform and stable black, meeting the color requirements of different application scenarios.

Good heat resistance: In the melt spinning process of polyester fibers, a higher processing temperature is usually required. The masterbatch has good heat resistance and can remain stable under high temperature conditions without affecting the molding and performance of the fiber.

Improving fiber properties: In addition to the coloring function, the addition of carbon black can also give the fiber a certain conductivity and reduce the electrostatic effect of the fiber, thereby improving the performance of the fiber during processing and use.

Environmental protection: It complies with relevant environmental protection standards, such as RoHS certification.

| Appearance | White or light-colored granules | Uniform granules, free of impurities. |

| Carrier Resin | Polypropylene (PP) | Excellent compatibility with PP melt-blown fabrics. |

| Electret Agent Content | 1%-5% | Adjustable based on filtration efficiency requirements. |

| Melt Flow Index (MFI) | 20-50 g/10min | High fluidity, suitable for melt-blown processes. |

| Density | 0.9-1.1 g/cm³ | Close to the density of PP resin, ensuring easy dispersion. |

| Heat Resistance | ≤ 150°C | Suitable for the processing temperatures of melt-blown processes. |

| Filtration Efficiency | ≥ 95% (for PM2.5, bacteria, etc.) | Meets KN95, N95, and other mask standards. |

| Breathing Resistance | ≤ 350 Pa | Low breathing resistance for enhanced comfort. |

| Environmental Compliance | RoHS, REACH compliant | Non-toxic and safe for medical and hygiene applications. |

| Packaging | 25kg/bag | Standard packaging, customizable based on customer requirements. |

Application scenarios

Textile industry: Mainly used to produce black polyester fibers, which can be used to make various textiles, such as clothing fabrics, home textile products, industrial fabrics, etc. For example, the production of black polyester shirt fabrics, black curtain fabrics, etc.

Industrial field: Due to its conductive properties, it can be used to produce antistatic fibers, which are widely used in electronic, chemical and other industrial places that are sensitive to static electricity. For example, it is used in antistatic work clothes and antistatic packaging materials in electronics factories.

Automotive interior: It can be used to produce interior materials such as car seat fabrics and roof fabrics. It not only provides a beautiful black appearance, but also meets the heat resistance and wear resistance of automotive interior materials.

Outdoor products: It can be used to make fabrics for outdoor tents, backpacks and other products. Black polyester fiber has good weather resistance and durability.

Get in Touch With Us

Who Are We?

Changzhou Runyi New Material Technology Co., Ltd.

News

-

The Science of Black: Optimizing Polymer Performa...

The Engineering Role of Carbon Black Masterbatch In the polymer industry, the carbon black masterbatch is far more ...

READ MORE -

Material Science of Pigmentation: Achieving Carri...

The selection of a Carbon Black Masterbatch is a technical exercise that extends far beyond color matching. For B2B...

READ MORE -

Engineered Longevity: Carbon Black Masterbatch UV...

In applications demanding extended outdoor performance—such as pipes, geosynthetics, and agricultural films—the sta...

READ MORE -

Precision Pigmentation: Mastering the FPV and Dis...

For processors involved in manufacturing thin-gauge films, fine fibers, or sophisticated injection molded component...

READ MORE -

MFR Matching Principle: Optimizing White Masterba...

In the realm of polymer processing, achieving consistent color dispersion and flawless product quality is a fundame...

READ MORE

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى