Non-Woven Fabrics Spunbond Nonwovens Carbon Black Masterbatch

Carbon black masterbatch is used as a black pigment product in non-woven fabrics. Carbon black masterbatch is composed of carbon black and polymer. In the manufacturing process of spun-bond non-woven fabrics, carbon black masterbatch is used as a filler and Masterbatch can increase the hardness and wear resistance of fibers, improve the mechanical properties of fibers, and give non-woven fabrics a deep and uniform black color. The Non-Woven Fabrics Spunbond Nonwovens Carbon Black Masterbatch pigment in the carbon black masterbatch forms a supporting structure inside the fiber, improving the tensile strength and anti-folding properties of the non-woven fabric. As a color masterbatch, carbon black masterbatch can ensure uniform color distribution in non-woven fabrics and prevent color from becoming lighter or discolored.

Description

Product introduction: PP new material base, 45% high purity, high pigment carbon black masterbatch, add a variety of additives, It is made with unique technology.

Add ratio: 2%~4%

This black masterbatch is tailor-made for PP non-woven fabric, a special material, and is also used for coloring PP polypropylene chemical fiber.

High-performance carbon black masterbatch, with polypropylene (PP)/polyester (PET) as carrier resin, carbon black content of 40-50%, designed for high-speed spinning process. The product adopts nano-scale carbon black dispersion technology to ensure zero pigment precipitation during fiber forming, significantly improving the uniformity and mechanical properties of non-woven fabrics.

Core advantages:

Efficient coloring: 1.5-3% addition can achieve deep black uniform coloring, and the hiding power is 30% better than the industry standard

Functional enhancement: Simultaneously impart anti-ultraviolet (UV ≥ 8 levels), anti-static (surface resistance ≤ 10^9Ω) and thermal conductivity properties

Process adaptation: Melt index range 25-35g/10min (230℃/2.16kg), perfect match 250-350m/min high-speed spunbond production line

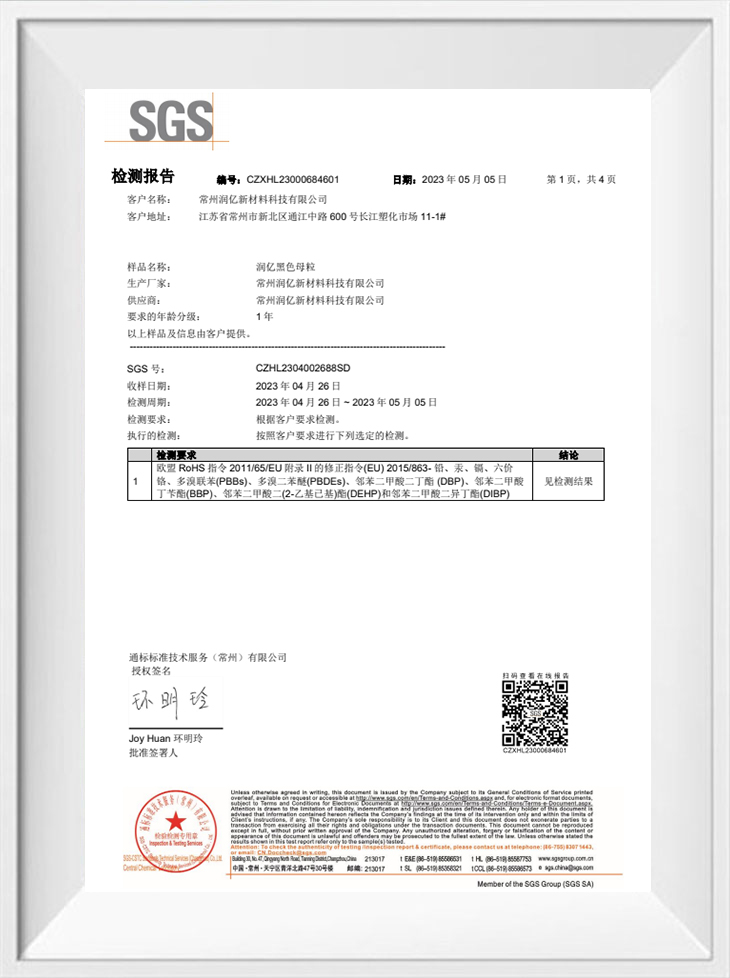

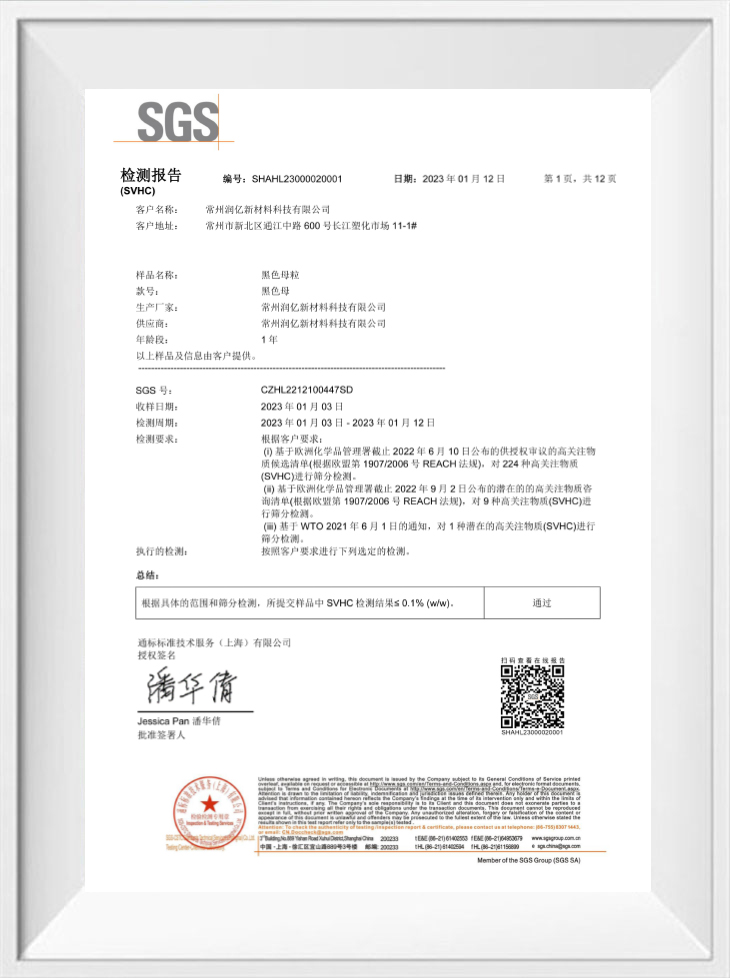

Applicable to high-end fields such as medical protection, agricultural mulch, sanitary materials, etc., and passed FDA, RoHS and ISO10993 biocompatibility certification. We provide customized formulation services to help customers optimize cost structure, and can reduce costs by 8-12% per ton of products.

Get in Touch With Us

Who Are We?

Changzhou Runyi New Material Technology Co., Ltd.

News

-

The Science of Black: Optimizing Polymer Performa...

The Engineering Role of Carbon Black Masterbatch In the polymer industry, the carbon black masterbatch is far more ...

READ MORE -

Material Science of Pigmentation: Achieving Carri...

The selection of a Carbon Black Masterbatch is a technical exercise that extends far beyond color matching. For B2B...

READ MORE -

Engineered Longevity: Carbon Black Masterbatch UV...

In applications demanding extended outdoor performance—such as pipes, geosynthetics, and agricultural films—the sta...

READ MORE -

Precision Pigmentation: Mastering the FPV and Dis...

For processors involved in manufacturing thin-gauge films, fine fibers, or sophisticated injection molded component...

READ MORE -

MFR Matching Principle: Optimizing White Masterba...

In the realm of polymer processing, achieving consistent color dispersion and flawless product quality is a fundame...

READ MORE

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى