Organic Biodegradable Antibacterial PA/PLA/PP Masterbatch

Organic biodegradable antibacterial PA/PLA/PP masterbatch is a high-performance plastic additive that combines biodegradation and antibacterial functions. This masterbatch is designed to solve the problems of traditional plastics being difficult to degrade and prone to breeding bacteria after use. The biodegradable components in the masterbatch can be decomposed by microorganisms under certain conditions. The addition of antibacterial function gives this masterbatch an advantage when manufacturing medical devices, food packaging and other products that require high hygiene requirements. Antibacterial ingredients can effectively inhibit the growth of bacteria and reduce the risk of product contamination during use.

Description

Antibacterial masterbatch is a kind of special raw material. It is used to manufacture materials with antibacterial function by adding one or more antibacterial agents to the production process. It is mixed with textile raw materials and processed. Widely used in medical, catering, home, and other fields, for people to provide.

The main function of an antibacterial masterbatch is to inhibit the reproduction of bacteria. Bacteria are microorganisms that can grow and reproduce in a variety of environments, and some of them cause disease. Antibacterial masterbatch can inhibit the reproduction of bacteria. Reduce the harm of bacteria to the human body. In addition, antibacterial masterbatches can also extend the shelf life of products such as food and maintain the freshness and taste of products.

Organic Biodegradable Antibacterial PA/PLA/PP Masterbatch is a multifunctional masterbatch that integrates biodegradable and antibacterial functions. It is suitable for materials such as polyamide (PA), polylactic acid (PLA) and polypropylene (PP). The product uses natural organic ingredients and environmentally friendly antibacterial agents. It can ensure that the material is biodegradable while providing efficient antibacterial performance, meeting modern environmental protection and health needs. It is widely used in food packaging, medical devices, daily consumer goods and other fields.

| Biodegradable | Made with natural organic components, ensuring the material can naturally degrade after use, reducing environmental pollution. |

| High Antibacterial Efficiency | Incorporates eco-friendly antibacterial agents, significantly inhibiting common bacteria such as E. coli and Staphylococcus aureus. |

| Wide Applicability | Suitable for PA, PLA, PP, and other materials, meeting diverse application needs. |

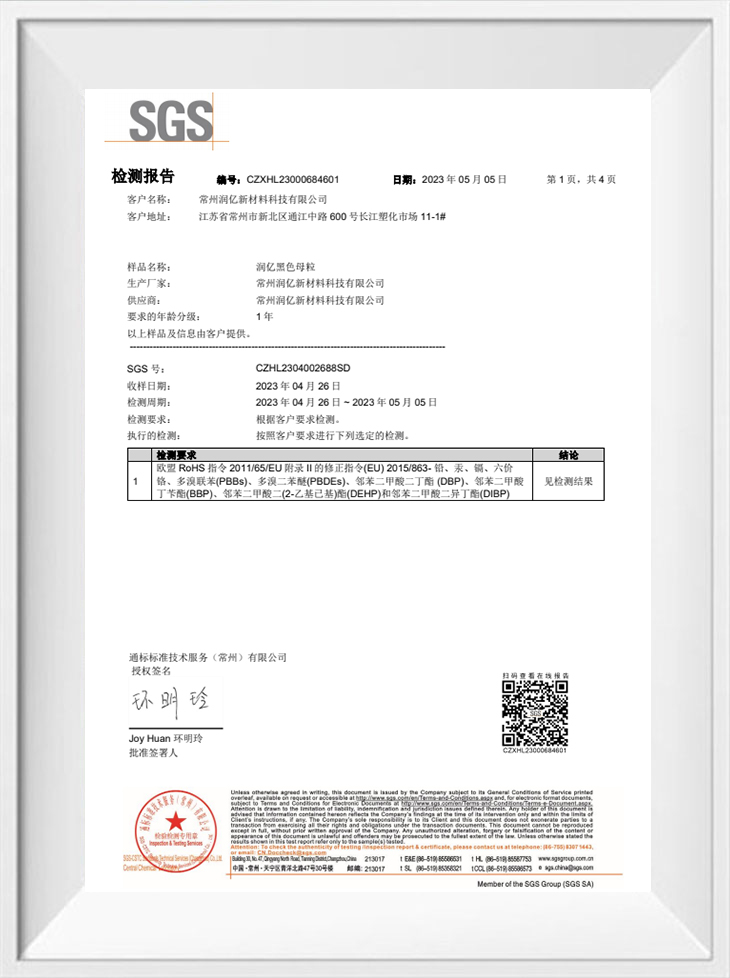

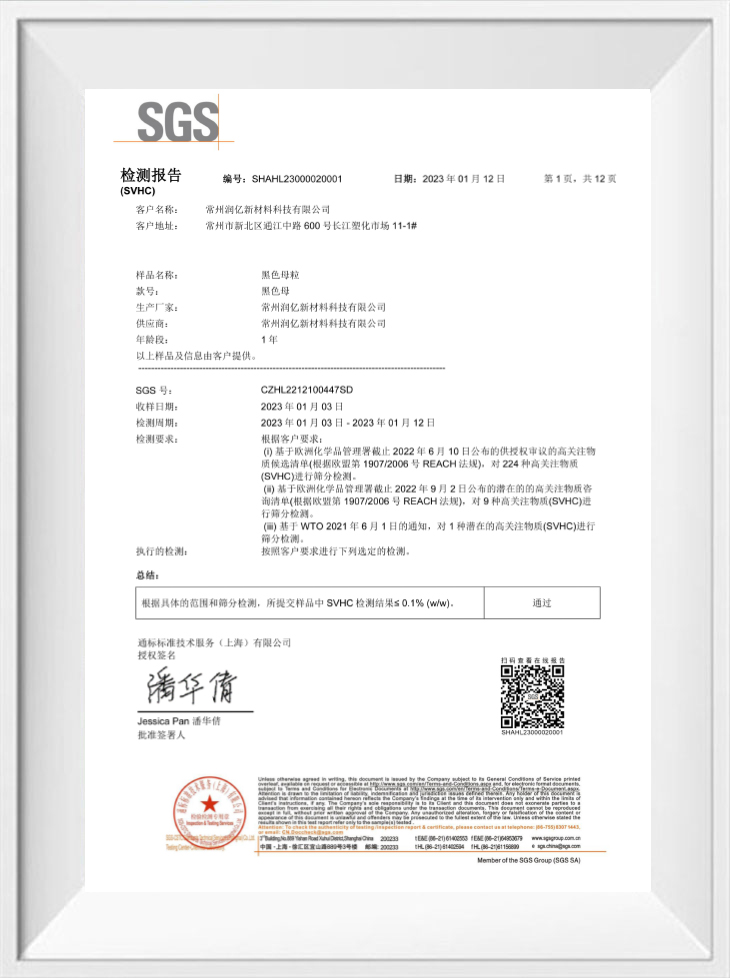

| Eco-friendly and Safe | Complies with RoHS, REACH, and other environmental standards, making it non-toxic and safe for food contact and medical applications. |

| Color Options | Available in transparent or customized colors to meet specific customer requirements. |

Application scenarios

Food packaging

Used to produce degradable food packaging films, tableware, beverage bottles, etc.

Provide antibacterial functions to extend the shelf life of food while ensuring that the material is environmentally friendly and degradable.

Medical devices

Used to produce disposable medical devices, surgical gowns, masks, etc.

Provide efficient antibacterial performance and meet the safety and environmental protection requirements of the medical field.

Daily consumer goods

Used to produce degradable plastic bags, household items, toys, etc.

Meet consumers' needs for environmental protection and health.

Agricultural films

Used to produce degradable ground films, greenhouse films and other agricultural films.

Provide antibacterial function, reduce crop diseases, and ensure that the material is environmentally friendly and degradable.

| Appearance | Granular | Uniform granules, free of impurities. |

| Carrier Resin | PA/PLA/PP | Excellent compatibility with PA, PLA, and PP resins. |

| Antibacterial Agent Content | 1%-5% | Adjustable based on antibacterial performance requirements. |

| Melt Flow Index (MFI) | 5-30 g/10min (adjusted based on carrier resin) | Suitable for injection molding, extrusion, and other processing techniques. |

| Density | 1.0-1.4 g/cm³ | Close to the density of PA, PLA, and PP resins, ensuring easy dispersion. |

| Antibacterial Performance | Antibacterial rate ≥ 99% | Significantly inhibits common bacteria such as E. coli and Staphylococcus aureus. |

| Degradability | Complies with ISO 14855 | Capable of biodegrading in natural environments. |

| Environmental Compliance | RoHS, REACH compliant | Non-toxic and safe for food contact and medical applications. |

| Packaging | 25kg/bag | Standard packaging, customizable based on customer requirements. |

Product advantages

Environmentally friendly and degradable: using natural organic ingredients to ensure that the material can be naturally degraded after use, reducing environmental pollution.

Highly effective antibacterial: has a significant inhibitory effect on common bacteria, improving the hygiene and safety of the product.

Wide applicability: Applicable to a variety of materials such as PA, PLA, PP, etc., to meet different application requirements.

Environmentally friendly and safe: in line with international environmental standards, suitable for food contact and medical fields.

Customized service: provide customized products with different antibacterial properties and colors according to customer needs.

Get in Touch With Us

Who Are We?

Changzhou Runyi New Material Technology Co., Ltd.

News

-

Engineered Longevity: Carbon Black Masterbatch UV...

In applications demanding extended outdoor performance—such as pipes, geosynthetics, and agricultural films—the sta...

READ MORE -

Precision Pigmentation: Mastering the FPV and Dis...

For processors involved in manufacturing thin-gauge films, fine fibers, or sophisticated injection molded component...

READ MORE -

MFR Matching Principle: Optimizing White Masterba...

In the realm of polymer processing, achieving consistent color dispersion and flawless product quality is a fundame...

READ MORE -

Achieving Flawless Quality: An Engineer's Guide t...

Introduction: The Business Case for Perfect Dispersion For B2B manufacturers in the plastics industry, the quality ...

READ MORE -

Enhancing Brightness and Hiding Power of White Pl...

1. Introduction In modern plastic manufacturing, achieving both a pristine white appearance and excellent hiding po...

READ MORE

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى