Description

Pa-103 high-performance black masterbatch is polymerized with organic pigment using PA resin as the carrier, which has dispersibility, high gloss, high blackness, and high coloring power. In the production process of PA6, PA66 modified glass fiber reinforcement, PA6, and PA66 injection molding products, The use of this product has a very low impact on the mechanical and electrical properties of PA6 and PA66 products and has no impact on CTI indicators (leakage marks). The product surface is beautiful, high black, high light, and no floating fiber phenomenon.

PA-103 high-performance black masterbatch can be blended with PA6, and PA66 injection molding, add 1%-2%, in PA6, The use of PA66 glass fiber reinforced modification is added according to the glass fiber content, GF30 recommends adding 1% PA-103 + 1.5% carbon black masterbatch; GF35 to GF45 recommend the addition of 1.5% PA-103 + 1% carbon black masterbatch. If it is required for CTI and laser welding, it is recommended to add 2%-2.5% PA-103 (do not use carbon black masterbatch).

25 kg/ bag composite packaging bag. Store in a dry place.

Recommended storage period: If stored as instructed, up to one year, more than one year later, it is recommended to re-test the moisture content before use.

Main features:

High concentration coloring: PA-103 black masterbatch uses high-quality carbon black pigment to ensure high color concentration and achieve uniform color effects.

Thermal stability: Excellent thermal stability, suitable for high temperature processing conditions, and can withstand high processing temperatures.

Light stability: Strong resistance to UV and oxygen, can effectively extend the service life of the product, especially suitable for outdoor applications.

Good dispersibility: The masterbatch has excellent dispersibility and can maintain a uniform dispersion effect during plastic processing to avoid color differences.

Enhanced mechanical properties: Not only can it provide excellent coloring effects, but it can also improve the physical and mechanical properties of plastic products, enhance their tensile strength and wear resistance.

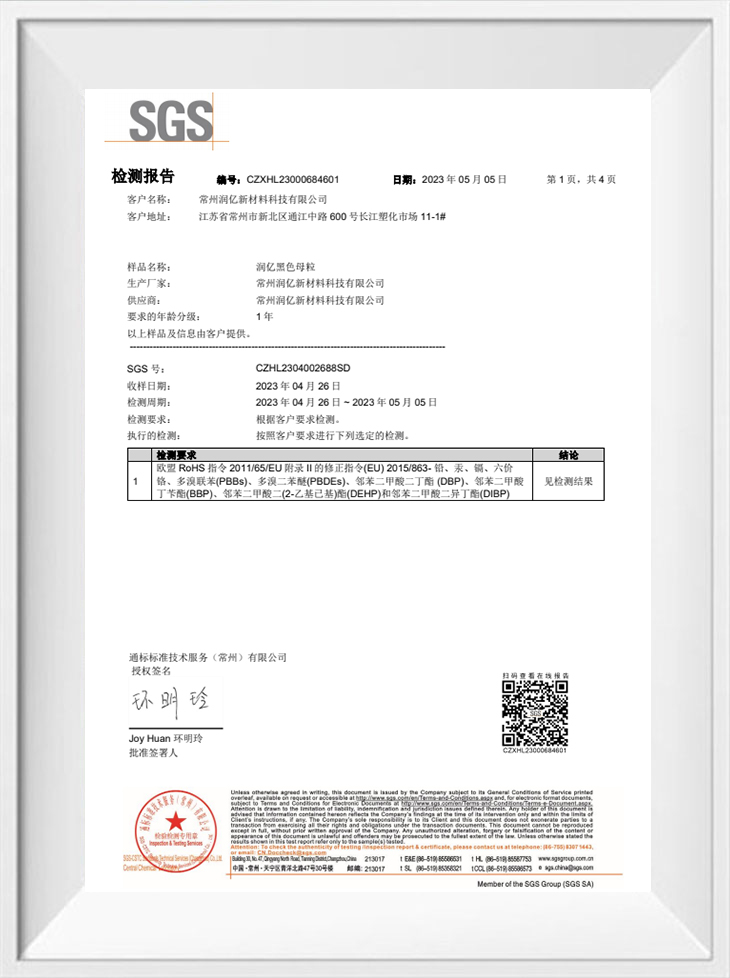

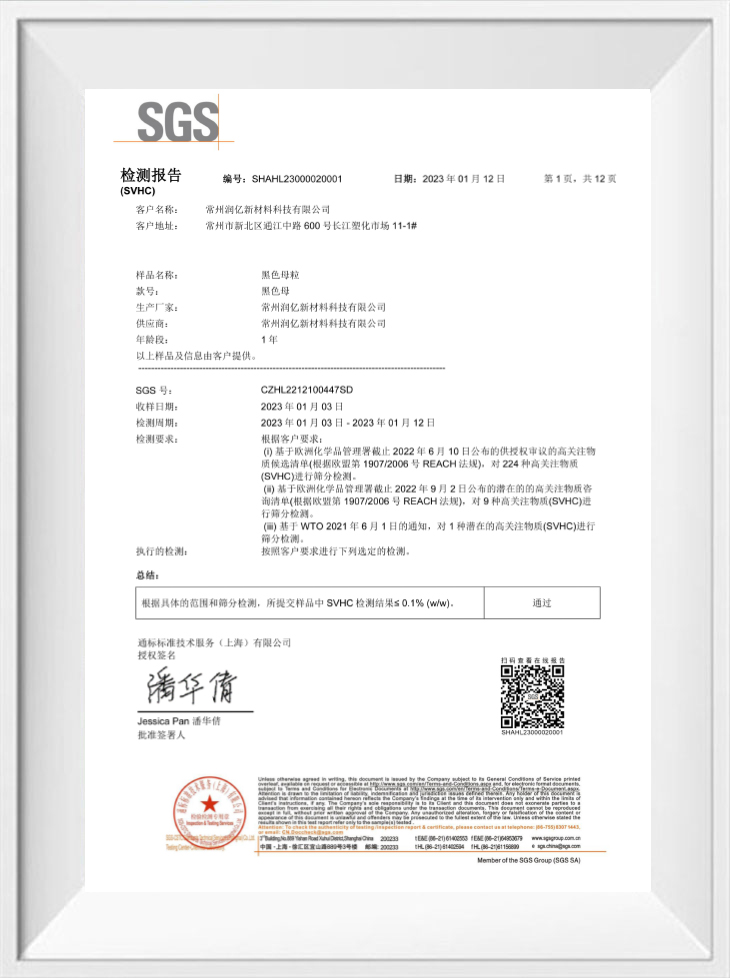

Environmental protection: It uses environmentally friendly materials, complies with international environmental standards (such as RoHS and REACH), and is non-toxic and harmless.

Technical parameters:

| Parameter | Value |

| Appearance | Black granules |

| Carbon black content | 40-60% (customizable) |

| Melt flow rate | 5-20 g/10min (190°C/2.16kg) |

| Temperature range | -30°C to 260°C |

| Solubility | Good |

| Particle size | 100-500 μm |

| Recommended processing temperature | 230°C - 290°C |

| Recommended addition | 2%-10% (adjusted according to application requirements) |

Scope and application fields: PA-103 black masterbatch is widely used in many fields, especially for coloring and reinforcing high-performance engineering plastics and composite materials.

Automotive industry:

Applicable to the coloring and enhancement of automotive interior and exterior trims (such as dashboards, door panels, seats, external housings, etc.), especially those used under high temperature and ultraviolet radiation.

Electronic appliances:

Used in plastic parts such as electronic product housings, wires and cables, sockets, etc., which can effectively provide strong electrical performance and weather resistance.

Building materials:

Used in plastic pipes, window frames, door frames and other products in the construction industry, which can effectively resist ultraviolet rays and are suitable for outdoor applications.

Consumer products:

Applicable to the coloring of household appliances, kitchen utensils, sports equipment, etc., ensuring elegant and durable appearance.

Packaging industry:

Applicable to plastic packaging for food, cosmetics and medicines, with good light-shielding and UV resistance, protecting the contents from light.

Industrial field:

Used in the coloring of parts such as machinery, tools, and equipment housings to enhance product durability and anti-aging performance.

Get in Touch With Us

Who Are We?

Changzhou Runyi New Material Technology Co., Ltd.

Honors and Qualifications

News

PA-103 Multipurpose High Performance Stability Black Masterbatch Industry knowledge

Can High-Performance Black Masterbatch Truly Enhance Plastic Mechanical Properties?

One of the most remarkable aspects of high-performance black masterbatch is its unique ability to maintain, and in some cases even enhance, the mechanical properties of the base plastic while incorporating pigment. This characteristic sets it apart as a valuable additive in the plastics industry, offering manufacturers a means to achieve desired coloration without compromising the structural integrity or performance of their products.

The mechanical properties of plastics, including tensile strength, impact resistance, flexural strength, and dimensional stability, are crucial considerations in numerous applications across various industries. From automotive components to consumer goods and packaging materials, the integrity of plastic products directly impacts their functionality, durability, and overall quality. Therefore, any alteration to these mechanical properties must be carefully managed to ensure that the final product meets performance requirements and industry standards.

When incorporating colorants into plastics, manufacturers often face challenges related to maintaining mechanical properties. Traditional methods of coloring plastics, such as using liquid dyes or pigments, can weaken the material and compromise its structural integrity. In contrast, high-performance black masterbatch offers a solution that not only imparts deep black coloration but also preserves or enhances the mechanical properties of the base plastic.

The ability of high-performance black masterbatch to maintain mechanical properties is attributed to several factors:

Optimized Formulation: The formulation of high-performance black masterbatch is carefully engineered to ensure compatibility with a wide range of base plastics. By selecting the appropriate carrier resin and pigment concentration, manufacturers can minimize any negative impact on mechanical properties while achieving the desired color intensity.

Uniform Dispersion: The uniform dispersion of carbon black pigment within the carrier resin is crucial for maintaining mechanical properties. Proper dispersion ensures that the pigment particles are evenly distributed throughout the plastic matrix, minimizing areas of weakness or inconsistency that could compromise structural integrity.

Enhanced Strength: In some cases, high-performance black masterbatch may even contribute to enhancing the mechanical properties of the base plastic. Carbon black, the primary pigment used in the masterbatch, possesses reinforcing properties that can improve tensile strength and impact resistance, particularly in certain types of plastics.

Stabilization Effects: High-performance black masterbatch often includes additives designed to improve stability and performance under various conditions. These additives may enhance the thermal stability, weather resistance, or chemical resistance of the final product, further bolstering its mechanical properties and overall durability.

By leveraging the advantages of high-performance black masterbatch, manufacturers can achieve consistent coloration and maintain the mechanical integrity of their plastic products across a wide range of applications. Whether producing automotive components, electronic devices, or consumer packaging, the ability to enhance aesthetics without compromising performance is a significant advantage in today's competitive market.

Moreover, the use of high-performance black masterbatch contributes to the sustainability of plastic products by minimizing waste and optimizing production processes. By reducing the need for additional additives or secondary processing steps, manufacturers can streamline their operations and minimize environmental impact without sacrificing product quality or performance.

In conclusion, the ability of high-performance black masterbatch to maintain or enhance the mechanical properties of base plastics represents a significant advantage for manufacturers seeking to balance aesthetics with performance. By carefully formulating and incorporating masterbatch into their production processes, manufacturers can achieve desired coloration while ensuring that their products meet the rigorous demands of modern applications. As the plastics industry continues to evolve, the importance of innovative additives like high-performance black masterbatch will only continue to grow, driving advancements in both product design and manufacturing technology.

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى